|

|

Level A or Level A Deluxe

|

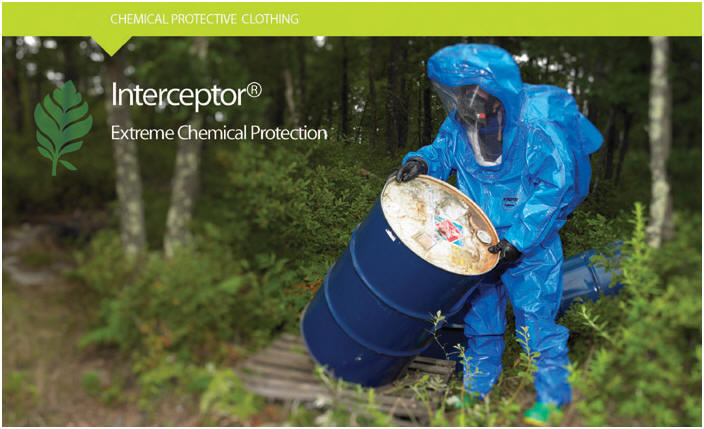

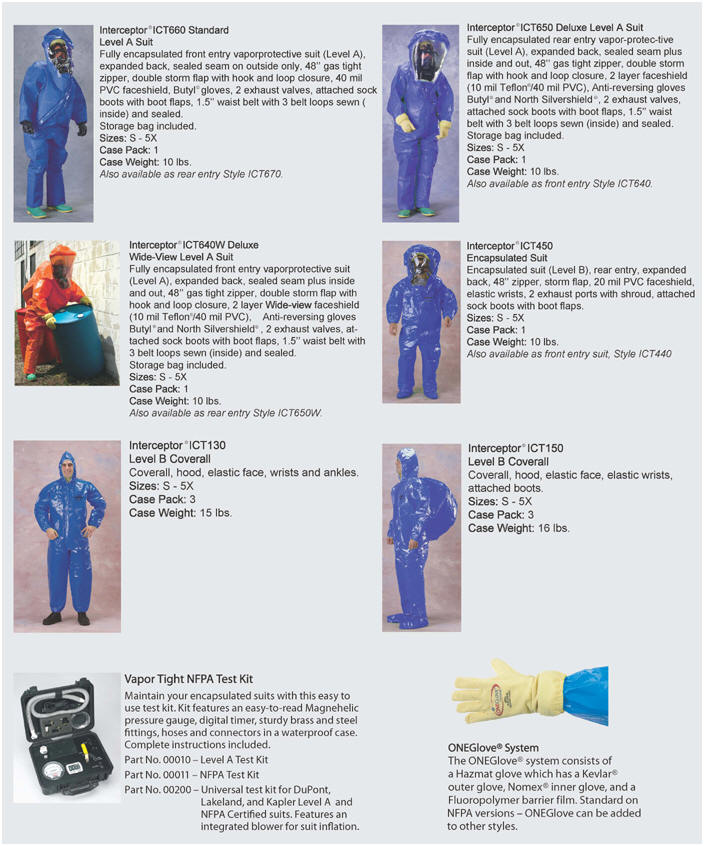

Interceptor®

Protective Layers

Interceptor uses a

combination of 8 barrier film layers and a non-woven

diffusion layer sequenced to optimize protection from

hazardous chemicals.

|

Interceptor® Seam

Style

Heat Sealed

|

ONEGlove® System

The ONEGlove® system

consists of a Hazmat glove which has a Kevlar® outer

glove, Nomex® inner glove and a Fluoropolymer barrier

film. Standard on NFPA versions - ONEGlove can be added

to other styles.

|

|

Passes the Limited

Chemical Flash Fire Protection for Escape and Liquified

Gas Protection option for NFPA 1991.

Aluminized/ Fiberglass

|

|

Vapor Tight NFPA

Test Kit

Maintain your

encapsulated suits with this easy to use test kit. Kit

features an easy-to-read Magnehelic pressure gauge,

digital timer, sturdy brass and steel fittings, hoses

and connectors in a waterproof case. Complete

instructions included.

- Part No. 00010 - Level A Test Kit

- Part No. 00011 - NFPA Test Kit

- Part No. 00200 - Universal Test Kit for DuPont,

Lakeland and Kapler Level A and NFPA Certified

suits. Features an integrated blower for suit

inflation.

|

We sell to Fire Departments!

|

Style No. |

Description |

| 80645 |

Blue Vapor

tight (Level A) NFPA 1991, 2005 Certified Ensemble -

Fully encapsulated, rear-entry vapor-protected suit |

| 80655 |

Blue Vapor

tight (Level A) NFPA 1991, 2005 Certified Ensemble -

Fully encapsulated, front-entry vapor-protected suit |

| 80645W |

Blue Vapor

tight (Level A) NFPA 1991 Ensemble - Fully encapsulated,

front-entry vapor-protected suit, wide view faceshield |

| 80655W |

Blue Vapor

tight (Level A) NFPA 1991 Ensemble - Fully encapsulated,

rear-entry vapor-protected suit, wide view faceshield |

| 80640 |

Blue CE

Type 1:EN943:2005 Vapor tight (Level A) Deluxe Ensemble

- Fully encapsulated, front-entry vapor-protected suit |

| 80650 |

Blue CE

Type 1:EN943:2005 Vapor tight (Level A) Deluxe Ensemble

- Fully encapsulated, rear-entry vapor-protected suit |

|

Permeation Data for ASTM Recommended List of

Chemicals for Evaluating

|

|

Chemical Name |

Physical Phase |

Normalized

Breakthrough

Time (min.) |

Cas No. |

| Acetone |

L |

>480 |

67-64-1 |

| Acetonitrile |

L |

>480 |

75-05-8 |

| Ammonia Gas |

G |

>480 |

7664-41-7 |

| 1,3-Butadiene Gas |

G |

>480 |

106-99-0 |

| Carbon Disulfide |

L |

>480 |

75-15-0 |

| Chlorine Gas |

G |

>480 |

7782-50-5 |

| Dichloromethane |

L |

>480 |

75-09-2 |

| Diethylamine |

L |

>480 |

109-89-7 |

| N,N-Dimethylformamide |

L |

>480 |

68-12-2 |

| Ethyl Acetate |

L |

>480 |

141-78-6 |

| Ethylene Oxide |

G |

>480 |

75-21-8 |

| n-Hexane |

L |

>480 |

110-54-3 |

| Hydrogen Chloride |

G |

>480 |

7647-01-0 |

| Methanol |

L |

>480 |

67-56-1 |

| Methyl Chloride |

G |

>480 |

74-87-3 |

| Nitrobenzene |

L |

>480 |

98-95-3 |

| Sodium Hydroxide, 50% |

L |

>480 |

1310-73-2 |

| Sulfuric Acid (conc.) |

L |

>480 |

7664-93-9 |

| Tetrachloroethylene |

L |

>480 |

127-18-4 |

| Tetrahydrofuran |

L |

>480 |

109-99-9 |

| Toluene |

L |

>480 |

108-88-3 |

|

> = greater than, L =

liquid, G = gas

Note: Chemical Restistance Data

is in accordance with ASTM F739 test method. Testing is

performed on fabric samples only, not finished garments.

Sources for all test data are independent laboratories.

All tests were performed under laboratory conditions and

not actual use conditions.

|

|

Permeation Data for 595 Class/Sublcass Chemical

Warefare Agents

|

|

Agent |

Common

Name |

Cas

Number |

Avg.

Breakthrough

Time |

| GA |

Tabun |

77-80-6 |

>60 min. |

| GB |

Sarin |

107-44-8 |

>60 min. |

| GD |

Soman |

99-64-0 |

>60 min. |

| HD |

Sulfur

Mustard |

505-60-2 |

>60 min.

>60 min. |

| L |

Lewisite |

541-25-3 |

>60 min. |

| VX |

VX |

50782-69-9 |

>60 min. |

|

![]()